Leather motorcycle jackets and pants were the most popular motorcycle clothing on the market due to its warmth retention, protection, tear resistance, etc. But as time goes on and with the advance of fabrics science and technology, textile fabrics have become more versatile and popular. The textile motorcycle clothing is the overwhelming favorite for riders who are looking for the best combination of performance,price, protection, and convenience.

The textile fabrics commonly used in motorcycle clothing can be classified into two categories in terms of its composition: polyester fabric and nylon fabric.

(1) First, let’s have a look at the similarities and differences between polyester and nylon fabrics. Polyester and nylon fabrics have a lot similar characteristics. They are both lightweight materials made from synthetic fibers. And they are both very popular options for motorcycle clothing. That is down to their durability-which is much better than that of natural fibers. And how well they respond to post-finishing processes that enhance their function. But there are also a lot of differences between polyester and nylon fabrics, which are embodied in the following three aspects.

(A). Feel& performance

Nylon is created as an alternative to silk, which has its soft and silky feel. It is also shinier and stretchier than polyester.

Polyester is generally a rougher, duller fabric. However, modern manufacturing practices have improved the feel of polyester. You can now find polyester that mimic the softness of cotton and is not so close to to the feel of nylon.

(B). Durability

Both nylon and polyester perform well in terms of strength and durability. But when we make a direct comparison, nylon is stronger and stretchier than polyester, meaning garments made from nylon should last longer.

(C).Reaction to water

When nylon gets wet it absorbs water and can expand up to 3.5%. So when you’re sweating or working out in the rain, it will take longer for nylon to dry.

Polyester, in comparison, is much less absorbent. It’s a hydrophobic fabric, which means any water will be pushed to the surface of the garment to evaporate. This makes it great for high-intensity sports where lots of perspiration is a given.

(2)Tensile strength and abrasion resistance of common fabrics in motorcycle clothing

Textile fabrics which are often used in motorcycle clothing are polyester 600D fabric, nylon 500D, 1050D nylon/Cordura, nylon/polyester 1680D and Cordura fabric(Cordura is a special kind of nylon fabric developed by Dupont).

Let’s take a closer look at these fabrics in terms of the tensile strength and abrasion-resistance.

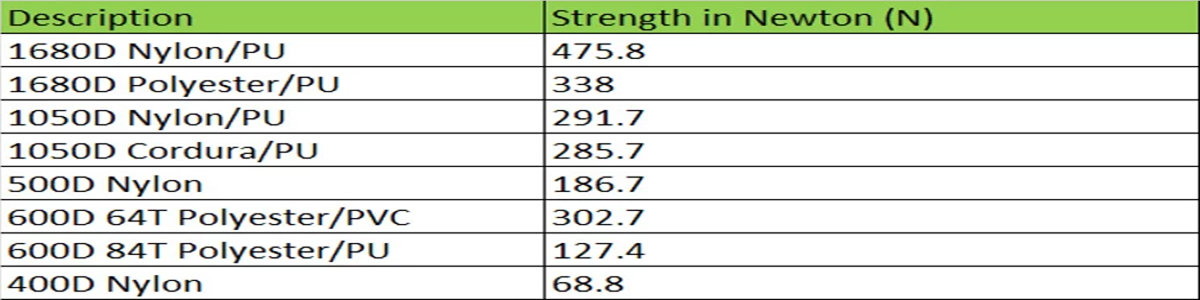

We have run them through our tensile strength test machine. The test method we have used this time is ASTM D 2261. We have done five tests per fabric to get the average data, and below is the result.

Two important conclusions can be drawn from the above test:

- Heavy weight fabric is stronger

Most of us believe heavier weight fabric is stronger than low weight fabric of the same kind. The test result proves that this belief is indeed TRUE, as we can see it from the above chart the more weight the fabric has, the more tensile strength it has.

- Nylon is stronger than Polyester

Although nylon and polyester fabrics look very similar, we commonly believe that nylon is stronger. This belief is also matching with our test result. When we compare 1680D Polyester verses 1680D Nylon, we have found that Nylon is 1.4 times stronger than Polyester. 500D Nylon is also about 1.4 times stronger than 600D Polyester.

However, tensile strength is not the only thing to consider when determining the durability of a fabric, the other important factor is its abrasion resistance.

The abrasion resistance test method we have used this time is the Martindale method (SATRA TM31-2003), with 12 kPa load, tested dry and under 25,600 cycles. The fabrics that we have tested this time are:

600D Polyester fabric.

500D Nylon fabric, which is often called 600D Nylon.

1050D Nylon fabric, which is often called 1000D Nylon.

The test results are:

600D Polyester: Moderate abrasion after 25,600 cycles

500D Nylon: Very slight abrasion after 25,600 cycles

1050D Nylon: Very slight abrasion after 25,600 cycles

This is a very good result. After 25,600 cycles, both 600D polyester and 500D nylon fabric hold pretty well. We can say that motorcycle clothing made of 600D Polyester should last for years under normal and fair usage.

Have you ever wondered why 600D Polyester is so popular even when it is not the strongest fabric out there? Why don’t outdoor brands just use Cordura for all of their products? The answer is very straight forward. It is because 600D Polyester is only half the price of 500D Nylon; fabric such as 1000D Nylon and Cordura are even more expensive. So, from the costing point of view, 600D Polyester is a very good choice. Even though it is not the strongest fabric available, it is still a very tough fabric.

To sum up, both 500D nylon and 600D polyester fabrics are well known for their good strength, durability and reasonable price. They are commonly used in the making of motorcycle clothing. When we make a decision on which fabric to use during product development of motorcycle clothing, we need to consider the product style, product market positioning, fabrics post-treatment and etc. Taian BOWINS Garment Co., Ltd. Has been dedicated to designing and manufacturing motorcycle clothing for over 15 years. If you have any questions or need help in selecting motorcycle clothing fabrics, please contact us for more detailed information at any time. We will be in touch as soon as possible.